PreForm allows the management of more than one printer and connects them together. You can schedule prints in PreForm and manage your printers. From slice to print, you can be done in minutes. It slices your model for your printer, automating layout, orientation, and supports, so all you need to do is press print. When you upload an STL or OBJ file into PreForm, it’s already connected to your Formlabs printer, so it knows what you want to do.

#Preform formlabs software#

Third-party software exists but PreForm is the only software built for Formlabs. If you own a Formlabs printer, you should always use PreForm. Unlike open-source slicing programs that are geared for FFF 3D printers, PreForm is designed specifically for SLA (Stereolithography), LFS (Light Force Stereolithography) and SLS (Selective Laser Sintering), supporting Formlabs 3D printers only. All you need to do is design your model in standard CAD software, then import the STL or OBJ file into PreForm and it will do the rest.

PreForm takes your 3D model file and slices it into the universal language of 3D printers, G-code. That’s great! But there is something wrong with the printer itself and I’ll take it apart to look for hints.What is Formlabs PreForm Software, and what does it do? This article provides an introduction to Formlabs’ slicing software.įormlabs Preform Software is proprietary slicing software for Formlabs 3D printers, meaning you need a Formlabs printer to use it. The good news is that all the aftermarket hardware I bought for this printer worked: the aftermarket AC power supply brick seemed to deliver enough power, the aftermarket resin hardened in response to the laser, and the aftermarket resin vat’s PDMS layer allowed the hardened resin to separate between layers. Wiping the resin vat clean of residue, I see a hole burned in the precious PDMS layer. I drained all of that contaminated resin into a disposal container that I will leave out in direct sunlight to harden. It also hardened various bits of resin which are now floating amongst still-liquid resin. The unmoving laser beam is what hardened the blob. The test clip was supposed to be close to the peeling hinge edge. This is definitely not the intended test clip object. I didn’t see movement from the resin vat, either, which was supposed to move as part of peeling process between layers.Īfter I cancelled the print job, the build platform was raised to its maximum height where I can confirm the misshapen blob. Watching the machine work, I could see the laser illuminated only a single spot instead of sweeping through the shape as I had expected. I had hoped to see a sturdy print raft forming the foundation of my test clip, but I saw only a lumpy misshapen blob. Roughly half an hour later, the print height has risen enough I could see between the print platform and the vat. I left the machine alone to do its thing. A good sign! Given the upside-down printing nature of resin printers, the metal printing platform blocked my view of what it was doing. I hit print and started hearing the buzzing of the Z-axis stepper motor. I installed the Form 1+ compatible aftermarket resin vat from Z-Vat industries, and poured in Form 1+ compatible aftermarket resin from ApplyLabWork.

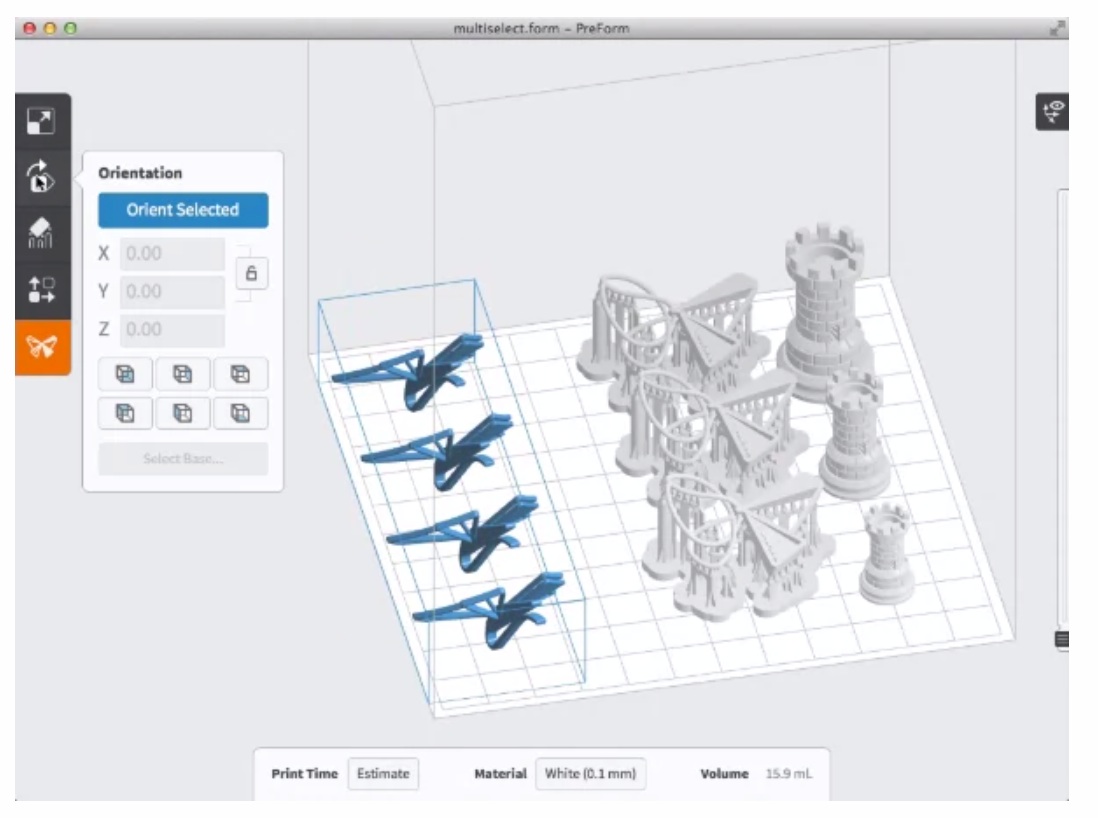

I followed through the tutorial to properly orient the shape and generate supports. Installing and launching PreForm activated an introduction to the software, which guides us through printing the FormLabs test object: a (hair?) clip in the shape of FormLabs butterfly logo. If someone wants to go even older because they have a need for 32-bit edition, PreForm 2.16.0 was the final 32-bit release and available on that same page.

#Preform formlabs download#

PreForm 2.20 is also available for download from the page listing PreForm versions and their equipment compatibility. That was the final release before PreForm dropped support for this old printer. I dug through FormLabs support to find this page Using PreForm with the Form 1+ which provides a link to download PreForm 2.20. With the hardware in hand, I moved on to the software side of things.Īll FormLabs equipment require their PreForm software to run, and the current version (3.25.2 as of writing) no longer supports the Form 1+. Working with FormLabs equipment isn’t cheap, and this “free as-is” printer required nearly $300 of stuff just so I could see if it even runs. I had been given a FormLabs Form 1+ resin printer that’s been sitting unused for years and requested to get it back up and running.

0 kommentar(er)

0 kommentar(er)